Professional Epoxy Floor Coating Services in Royal Oak, Michigan

"We're Bringing Life to Your Floors, One Coat at a Time!"

Request A Quote!

Royal Oak, MI - Epoxy Floor Coating

Transform your Royal Oak property with premium epoxy floor coating services from New Day Construction Services, your trusted local specialists with over 20 years of experience serving Oakland County. We begin every client relationship with superior residential painting services that demonstrate our quality and attention to detail, naturally progressing to comprehensive flooring solutions including garage floor epoxy, basement floor coating, and commercial-grade applications.

Our Royal Oak epoxy floor coating expertise combines advanced materials, proven application techniques, and meticulous surface preparation to deliver durable, beautiful floors that enhance your property value and provide lasting performance. Whether you're upgrading your garage, finishing your basement, or creating stunning decorative floors, our skilled team delivers exceptional results that exceed expectations.

Ready to upgrade your Royal Oak floors with professional epoxy coating? Call (313) 499-8891 for your free estimate and discover why homeowners throughout Oakland County choose New Day Construction Services for painting and flooring excellence.

Comprehensive Royal Oak Epoxy Floor Solutions

Our epoxy floor coating services in Royal Oak encompass residential, commercial, and industrial applications, utilizing premium materials and advanced techniques that ensure superior adhesion, durability, and aesthetic appeal for every project.

Residential Garage Floor Epoxy

Garage floor epoxy represents our most popular service, transforming ordinary concrete into stunning, durable surfaces that resist stains, chemicals, and daily wear. Royal Oak homeowners choose our garage epoxy coating for its exceptional durability, easy maintenance, and dramatic aesthetic improvement that complements their home's value.

Our residential garage floor process begins with thorough concrete preparation including diamond grinding, crack repair, and moisture testing to ensure optimal adhesion. We use premium 100% solids epoxy systems that provide superior performance compared to water-based alternatives, creating floors that withstand automotive fluids, road salt, and heavy traffic.

Royal Oak's historic neighborhoods and diverse architectural styles benefit from our customizable approach. Whether your home features a traditional colonial garage or modern attached structure, our

garage floor epoxy solutions complement your property's character while providing practical benefits including stain resistance, easy cleaning, and enhanced lighting reflection.

Basement Floor Coating Excellence

Basement floor coating creates comfortable, functional living spaces while addressing moisture concerns common in Royal Oak's clay soil conditions. Our epoxy basement floors provide moisture resistance, easy cleaning, and attractive finishes that support various uses from recreation rooms to home offices.

Royal Oak's established neighborhoods often feature older homes with basement moisture challenges. Our moisture-mitigating primers and vapor barrier systems ensure long-lasting performance even in challenging conditions. The result is a beautiful, durable floor that transforms your basement into valuable living space while addressing practical concerns.

Commercial and Industrial Applications

Our commercial epoxy flooring serves Royal Oak businesses requiring durable, safe, and attractive floor solutions. From retail spaces along Main Street to manufacturing facilities, we provide customized systems that meet specific performance requirements including chemical resistance, slip resistance, and aesthetic specifications.

Royal Oak's vibrant business district benefits from our commercial flooring expertise, creating professional environments that enhance customer experience while providing practical durability for daily operations.

About Us

How We Can Help...

At New Day Detroit Construction, we're committed to bringing your floors to life with our professional epoxy floor coating services. We understand the importance of a durable, long-lasting floor, and that's exactly what our epoxy coatings provide. We're proud to serve the good folks of Royal Oak, MI, offering a flooring solution that's not just about looks but also about functionality. We're detail-oriented in our work, ensuring each project is completed with precision and professionalism. You can count on us for reliable service and an end result that truly stands the test of time.

Ready to add a splash of durability and style to your floors?

Interested in learning more about the many services New Day Construction offers, use our AI Chatbot and get your questions answered quickly and book your consultation at (313) 499-8891.

Advanced Epoxy Floor Coating Systems

Premium Material Selection

We exclusively use 100% solid epoxy systems that provide superior performance, durability, and longevity compared to water-based alternatives. Our material partnerships with leading manufacturers ensure access to the latest technologies and highest-quality products available.

Epoxy System Options:

- Standard Epoxy: Excellent durability for residential applications

- High-Performance Epoxy: Enhanced chemical and abrasion resistance

- Decorative Systems: Metallic, flake, and custom color options

- Anti-Slip Additives: Safety-focused solutions for high-traffic areas

Surface Preparation Excellence

Proper surface preparation determines the success and longevity of every epoxy floor coating project. Our comprehensive preparation process includes concrete assessment, diamond grinding, crack repair, and moisture testing to ensure optimal conditions for epoxy application.

Preparation Process:

- Concrete Assessment: Evaluation of substrate condition and suitability

- Diamond Grinding: Mechanical preparation for optimal adhesion

- Crack and Defect Repair: Structural repairs using appropriate materials

- Moisture Testing: Ensuring proper conditions for epoxy application

- Final Cleaning: Removal of all dust and contaminants

Professional Application Techniques

Our certified applicators use advanced application techniques including proper brush and roller selection, spray equipment when appropriate, and multiple coat systems for optimal coverage, durability, and appearance. Temperature and humidity control, proper mixing procedures, and timing coordination ensure optimal results for every Royal Oak project.

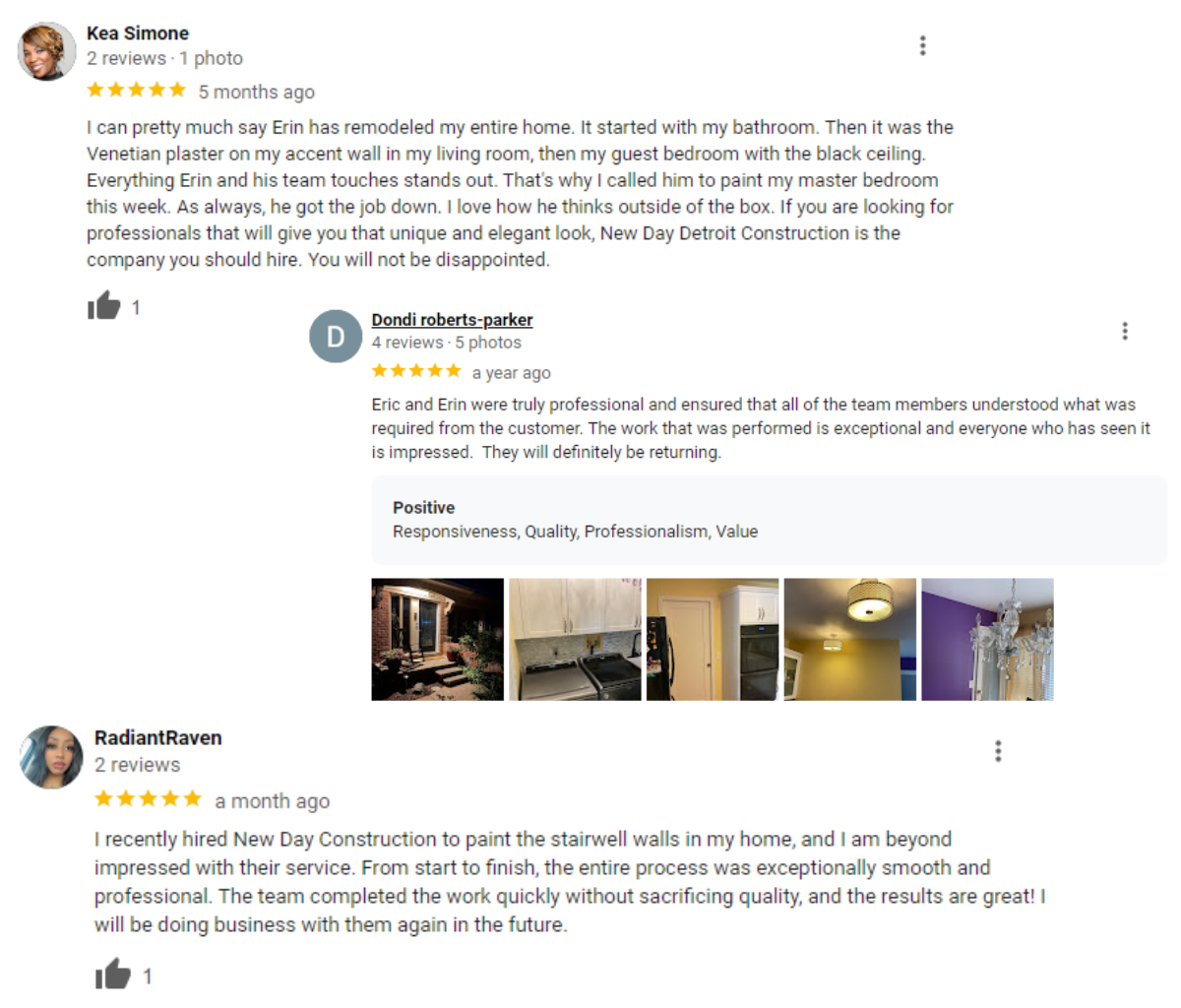

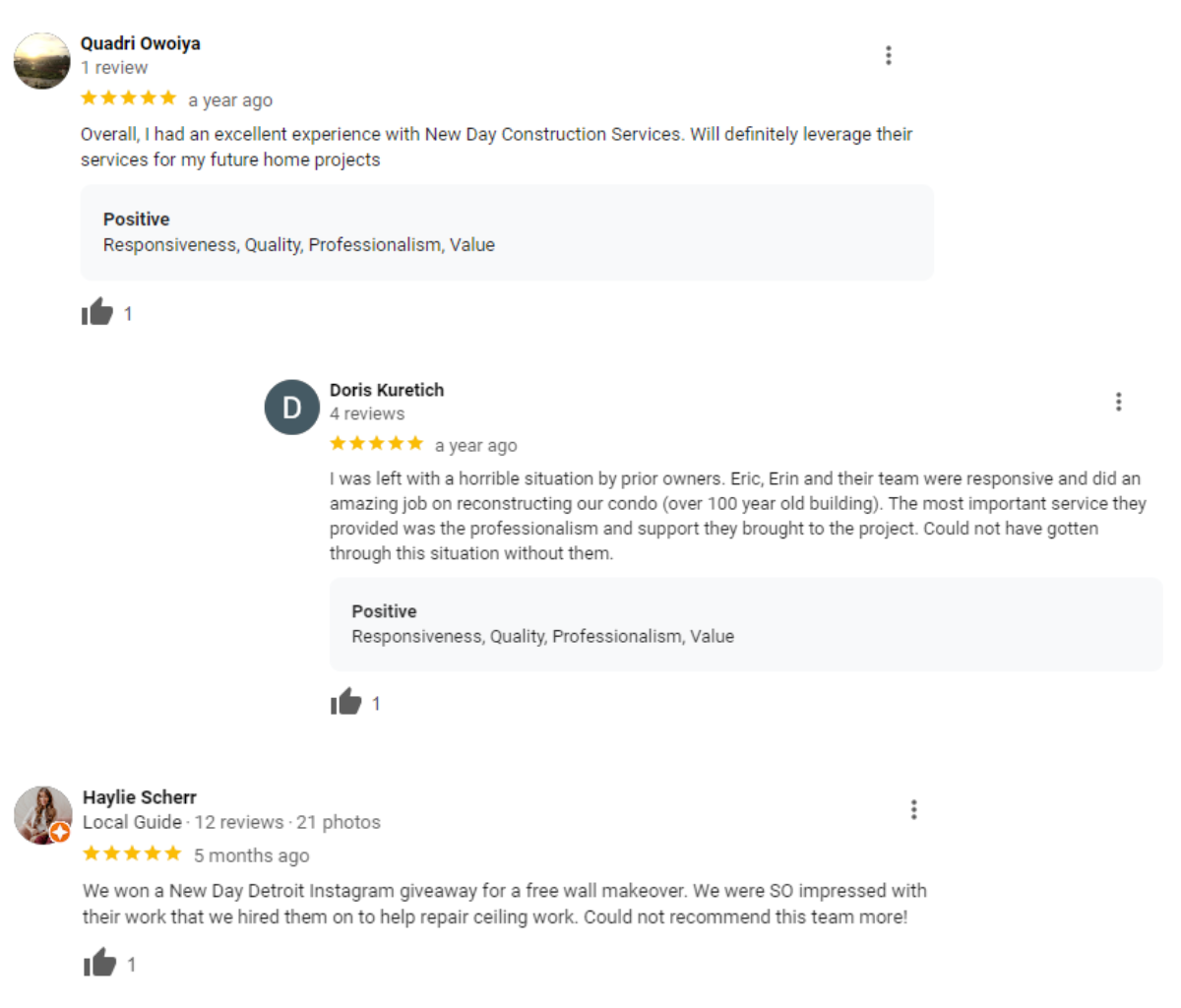

Testimonials

Why Choose New Day Construction Services

Painting-First Home Improvement Approach

New Day Construction Services begins every client relationship with superior residential painting services that showcase our attention to detail, quality materials, and professional standards. This foundation naturally grows into comprehensive home improvement including epoxy floor coating, kitchen remodeling, and complete property transformations.

Our painting-first approach allows Royal Oak homeowners to experience our quality through accessible services before investing in larger projects. When you see the transformation that professional painting brings to your home, you'll understand why our satisfied customers choose us for all their flooring and home improvement needs.

Local Royal Oak Expertise

Over 20 years serving Royal Oak and Oakland County has given us deep understanding of local conditions, architectural styles, and homeowner preferences. Our Royal Oak epoxy floor coating expertise addresses specific challenges including soil conditions, moisture patterns, and climate considerations.

We understand Royal Oak's diverse neighborhoods from historic downtown areas to modern subdivisions, tailoring our

epoxy flooring solutions to complement each property's unique characteristics and requirements. Our local presence ensures prompt service, ongoing support, and community accountability.

Licensed and Insured Excellence

We maintain comprehensive licensing and insurance coverage, providing complete protection and peace of mind for every epoxy floor coating project. Our professional credentials, safety protocols, and quality guarantees ensure your Royal Oak property and investment are protected.

Comprehensive Service Integration

Our

epoxy floor coating services integrate seamlessly with our comprehensive home improvement capabilities including

interior painting,

exterior painting,

kitchen remodeling,

bathroom renovation, and

basement finishing. This integration provides convenient, coordinated project management and consistent quality across all services.

Royal Oak Epoxy Floor Applications and Benefits

Garage Floor Transformation

Garage floor epoxy provides numerous benefits for Royal Oak homeowners including stain resistance, easy cleaning, enhanced lighting reflection, and dramatic aesthetic improvement. Our garage floor systems withstand automotive fluids, road salt, and heavy equipment while maintaining their appearance for years.

Chemical Resistance: Protection against oils, gasoline, and automotive fluids- Easy Maintenance: Simple cleaning with standard household products

- Enhanced Safety: Slip-resistant options and improved visibility

- Property Value: Significant increase in home value and appeal

Basement Floor Solutions

Basement floor coating addresses moisture concerns while creating attractive, functional spaces. Our moisture-mitigating systems and decorative options transform Royal Oak basements into valuable living areas suitable for recreation, offices, or storage.

- Moisture Resistance: Protection against humidity and minor water intrusion

- Comfort Enhancement: Warmer, more comfortable surfaces

- Versatile Design: Multiple color and texture options

- Space Utilization: Maximizes basement functionality and appeal

Decorative and Custom Options

Our decorative epoxy floor coating options allow Royal Oak homeowners to create unique, personalized floors that complement their home's aesthetic. From subtle solid colors to dramatic metallic finishes, we provide customization that reflects your style and preferences.

- Color Flake Systems: Broadcast flakes in various colors and sizes

- Metallic Epoxy: Stunning three-dimensional metallic effects

- Solid Colors: Clean, professional appearance in custom colors

Custom Designs: Logos, patterns, and specialized applications

Royal Oak Service Area and Local Authority

Comprehensive Royal Oak Coverage

We proudly serve all Royal Oak neighborhoods and surrounding Oakland County communities, providing prompt, reliable epoxy floor coating services with the personal attention that sets us apart from larger contractors.

Service Areas Include:

- Downtown Royal Oak: Historic properties and modern condominiums

- Northwood: Established residential neighborhoods

- Clawson Border: Adjacent community coverage

- Ferndale Border: Comprehensive regional service

- Birmingham Border: Premium residential applications

Local Market Understanding

Royal Oak's diverse residential market demands premium quality and exceptional service. Our epoxy floor coating solutions meet these expectations with superior materials, professional installation, and comprehensive warranties that protect your investment.

We understand local architectural styles, from mid-century modern homes to traditional colonials, ensuring our

epoxy flooring solutions complement each property's unique character and enhance its value.

Climate and Environmental Considerations

Michigan's challenging climate requires specialized

epoxy floor coating solutions that address freeze-thaw cycles, moisture variations, and seasonal temperature changes. Our material selection and application techniques account for these factors, ensuring long-lasting performance in Royal Oak conditions.

Ready to add a splash of durability and style to your floors?

Interested in learning more about the many services New Day Construction offers, use our AI Chatbot and get your questions answered quickly and book an consultation at (313) 499-8891.

Professional Installation Process

Initial Consultation and Assessment

Every epoxy floor coating project begins with comprehensive consultation including surface assessment, material recommendations, and detailed project planning. Our experienced team provides expert guidance on system selection, color options, and timeline coordination.

Surface Preparation and Repair

Proper preparation forms the foundation of successful epoxy flooring installation. Our thorough process addresses all surface conditions, ensuring optimal adhesion and long-lasting performance for your Royal Oak project.

Professional Application and Finishing

Our certified applicators use proven techniques and professional equipment to ensure uniform coverage, proper thickness, and flawless finishes. Quality control procedures and final inspection ensure every project meets our exacting standards.

Painting Service Directory

Interior/Exterior House Painters

Epoxy Floor Coating

Berkley, MI Epoxy Floor Coating

Canton, MI Epoxy Floor Coating

Detroit, MI Epoxy Floor Coating

Eastpointe, MI Epoxy Floor Coating

Farmington, MI Epoxy Floor Coating

Ferndale, MI Epoxy Floor Coating

Garden City, MI Epoxy Floor Coating

Grosse Pointe, MI Epoxy Floor Coating

Livonia, MI Epoxy Floor Coating

Oak Park, MI Epoxy Floor Coating

Redford, MI Epoxy Floor Coating

Royal Oak, MI Epoxy Floor Coating

Kitchen Cabinet Painters

Deck & Fence Painters

Berkley, MI Deck & Fence Painters

Canton, MI Deck & Fence Painters

Detroit, MI Deck & Fence Painters

Eastpoint, MI Deck & Fence Painters

Farmington, MI Deck & Fence Painters

Ferndale, MI Deck & Fence Painters

Garden City, MI Deck & Fence Painters

Grosse Pointe, MI Deck & Fence Painters

Livonia, MI Deck & Fence Painters

Oak Park, MI Deck & Fence Painters

Redford, MI Deck & Fence Painters

Royal Oak, MI Deck & Fence Painters

From Painting to Complete Home Improvement

New Day Construction Services begins every Royal Oak client relationship with superior residential painting services that demonstrate our quality and professionalism. This foundation naturally grows into comprehensive home improvement including epoxy floor coating, kitchen remodeling, bathroom renovation, and complete property transformations.

Integrated Home Improvement Solutions

Our epoxy floor coating services integrate seamlessly with our comprehensive capabilities, providing convenient project coordination and consistent quality. Many clients discover our flooring expertise through basement finishing or garage renovation projects that showcase our attention to detail.

Building Lasting Relationships

Our painting-first approach builds trust and confidence that leads to long-term relationships with Royal Oak families who rely on us for all their home improvement needs. From initial

interior painting to complete

home remodeling, we provide the expertise and service that exceeds expectations.

Get Your Free Royal Oak Epoxy Floor Estimate

Ready to transform your Royal Oak floors with professional epoxy floor coating? Contact New Day Construction Services today for your free estimate and consultation.

Call (313) 499-8891 now to schedule your free epoxy flooring estimate. Discover why Royal Oak homeowners have trusted New Day Construction Services for over 20 years for painting, flooring, and complete home improvement solutions.

Whether you're planning

garage floor epoxy,

basement floor coating, or considering complete home improvement, we provide the expertise, quality, and service that builds lasting relationships and creates beautiful homes throughout Royal Oak and Oakland County.

Everything you need, all in one place

20 Years of Pro Coating Experience

Discover the visual we can create in your space with our professional epoxy coating services.

Guaranteed Customer Satisfaction

We're committed to exceeding your expectations and transforming your interiors, one brush stroke at a time.

Reliable, Detail-Oriented Flooring Services

Don't wait, let's start coloring your world today!